Industrial steam boilers are large, complex systems that are used to generate steam for a variety of different industries and applications. These systems are used to generate steam for a variety of different purposes, including heating buildings, sterilizing medical equipment, and generating electricity.

Steam Boiler Solutions Guide – Steam boilers are an integral part of many industrial processes and play a critical role in producing heat and power. These boilers are used to heat water and create steam that is used in various processes, including heating, cooking, cleaning, and others.

Steam , as well as the key considerations to keep in mind when choosing the right steam boiler solution for your industry.

Types of Industrial Steam Boilers Systems

Fire-Tube Boilers

Fire-tube boilers are designed to facilitate efficient boiler combustion. are the simplest and most traditional type of steam boiler solutions. They consist of a cylindrical shell filled with water, with tubes running through the water that allow hot gases from a fire to circulate through the water and heat it.

These boilers are simple, efficient, and cost-effective, making them a popular choice for many industrial applications.

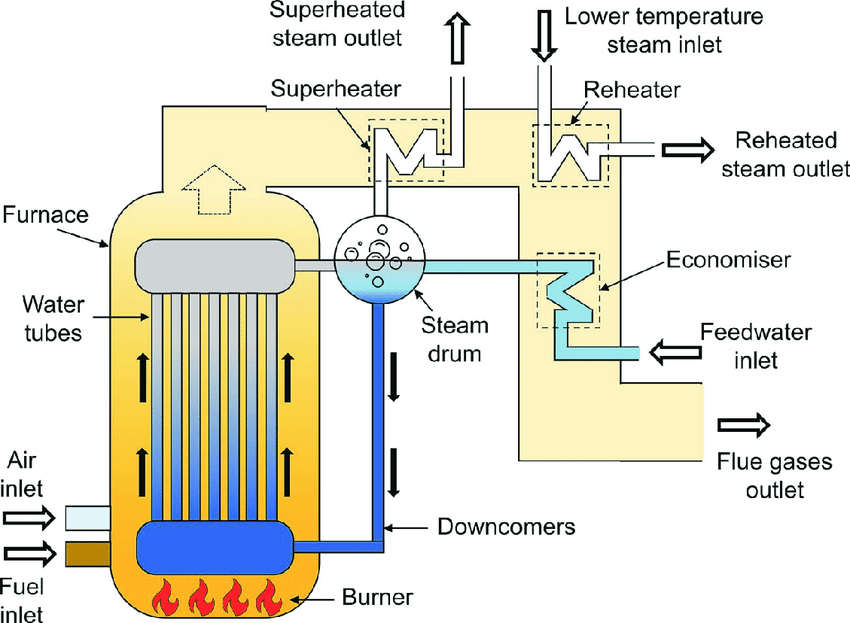

Water-Tube Boilers

Water-tube boilers are more complex than fire-tube boilers but offer several advantages over their simpler counterparts. In a water-tube boiler, the water is inside the tubes and the hot gases circulate around the outside of the tubes.

This design allows for faster heat transfer, increased efficiency, and the ability to generate steam at higher pressures. These boilers are commonly used in high-pressure and high-heat applications.

Package Boilers

These steam boiler solutions – Package boilers are pre-fabricated boilers that are shipped to the customer as a complete package, including all the necessary components, such as the boiler, burners, control systems, and others.

These boilers are ideal for customers who need a simple, turnkey solution for their steam needs.

Applications of Steam Boilers

Power Generation

Steam boilers play a critical role in power generation by converting water into steam to drive turbines and generate electricity. These boilers are used in power plants all over the world to generate electricity for homes, businesses, and industries.

Heating and Drying

Steam boilers are also used for heating and drying processes in a variety of industries, including food and beverage processing, paper and pulp production, and others. The steam generated by the boilers is used to heat air, dry products, or heat water for other processes.

Cleaning and Sterilization

Steam boilers are also used in cleaning and sterilization processes in a variety of industries, including healthcare, food and beverage, and others that require steam. The steam generated by the boilers is used to clean equipment, sanitize surfaces, and sterilize products.

Key Considerations When Choosing Steam Boiler Solutions

Capacity

When choosing a steam boiler solution, it is important to consider the capacity of the boiler, as well as the amount of steam that will be required. The capacity of the boiler will determine how much steam can be generated and the size of the system that is needed.

Efficiency

Efficiency is also an important consideration when choosing a steam boiler solutions. The efficiency of the boiler will determine how much fuel is required to generate a given amount of steam, and will have a direct impact on operating costs.

Cost

Cost is also an important consideration when choosing a steam boiler solution. The cost of the system will include the purchase price of the boiler, as well as any additional components and installation costs associated with the fired steam boiler.

It is important to consider the total cost of ownership, including operating costs, when making a decision.

Conclusion

Steam boilers are a critical component of many industrial processes, and it is important to choose the right fired steam boiler solution for your specific needs. By considering the different types of boilers, their applications, and key considerations such as capacity, efficiency, and cost, you can find the right steam boiler solution for your industry.

When choosing a steam boiler solution, it is also important to work with a knowledgeable and experienced supplier who can help you determine the right boiler to ensure your specific needs are met.

NIIFT is known for its innovative solutions in boiler technology, including the epcb boiler and Industrial Boiler Systems

The NIIFT ultimate guide to steam boiler solutions for industry provides a comprehensive overview of the different types of boilers, their applications, and the key considerations to keep in mind when choosing the right solution.

Whether you are in the power generation, heating and drying, or cleaning and sterilization industries, you can find the right steam boiler solution for your needs by considering these key factors and contacting NIIFT who are knowledgeable and experienced suppliers.

Frequently Asked Questions

Q: What are the primary industrial applications of steam boilers?

A: Steam boilers are used in various industrial applications, including power generation, food processing, chemical manufacturing, and textile production, where they produce steam or hot water for heating and energy needs.

Q: What are the key components of a steam boiler?

A: The key components of a steam boiler include the burner, combustion chamber, heat exchanger, water feed system, and safety devices. Each of these components plays a crucial role in ensuring the safe operation of the boiler to ensure and maximizing boiler performance.

Q: How does a firetube boiler operate?

A: A firetube boiler operates by having hot gases from combustion pass through tubes that are submerged in water, heating the water and converting it into steam. This type of boiler is known for its reliability and efficiency in producing steam.

Q: What is the importance of boiler design in steam boiler operation?

A: Boiler design is critical in steam boiler operation as it affects efficiency, safety, and performance. Proper design ensures that the boiler operates within optimal parameters, allowing for the effective conversion of water into steam.

Q: How do gas-fired steam boilers differ from electric steam boilers?

A: Gas-fired steam boilers use natural gas or propane as a fuel source, while electric steam boilers use electricity to heat the water. Gas-fired boilers typically have higher steam pressure capabilities and are suitable for larger industrial applications, whereas electric boilers are often used in smaller settings where space and fuel supply are limited.

Q: What is the role of boiler water in steam production?

A: Boiler water is essential for steam production as it is heated and converted into steam inside the boiler. The quality of the water to the boiler affects the efficiency and longevity of the boiler, so it must be treated to prevent scale and corrosion.

Q: How can I ensure that the boiler operates safely?

A: To ensure that the boiler operates safely, regular maintenance is essential, including checking the boiler components, monitoring steam pressure, and conducting safety inspections. Additionally, following manufacturer guidelines and industry standards is crucial for safe operation.

Q: What is the significance of high-pressure steam in industrial applications?

A: High-pressure steam is significant in industrial applications as it provides greater energy efficiency and allows for the transportation of steam over long distances. It is commonly used in processes that require significant heat energy, such as in power plants and manufacturing facilities that require steam.

Q: What should be done if the steam supply is inconsistent?

A: If the steam supply is inconsistent, it is important to check for potential issues such as low water levels, malfunctioning boiler components, or improper settings. Regular maintenance and monitoring can help identify and resolve these issues to ensure reliable steam production.